In today’s automotive world, the challenge isn’t just building faster engines it’s building cleaner, safer, and smarter vehicles. Activated carbon plays a behind-the-scenes but mission-critical role in controlling emissions, protecting cabin air quality, and meeting global environmental standards.

Modern vehicles use EVAP (Evaporative Emission Control) systems to prevent the escape of fuel vapors during parking, refueling, and heat buildup. These systems rely on advanced pelletized or granulated activated carbon to adsorb volatile hydrocarbons such as gasoline vapor, hexane, benzene, and toluene.

Vitronexa Carbon is specially engineered with low attrition and optimized pore structure to ensure maximum vapor retention and long-term stability. By capturing and later purging these vapors into the engine for combustion, it supports cleaner emissions, improved fuel efficiency, and compliance with global standards like Euro 6, EPA Tier 3, and BS-VI.

In modern vehicle cabins, ensuring clean, breathable air is essential especially for passengers sensitive to allergens, odors, and gaseous pollutants. Cabin air filters combine advanced HEPA filtration with activated carbon layers to trap harmful compounds like formaldehyde, nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs).

To enhance this protection, Vitronexa Carbon’s microgranular or PAC-coated nonwoven formulations are engineered to absorb even the most persistent airborne contaminants, including cigarette smoke and food odors. This integration improves passenger comfort, protects sensitive individuals from irritation, and delivers a quieter, fresher ride experience. Our solutions are widely adopted across passenger vehicles, luxury fleets, and emergency ambulances requiring medical-grade air quality.

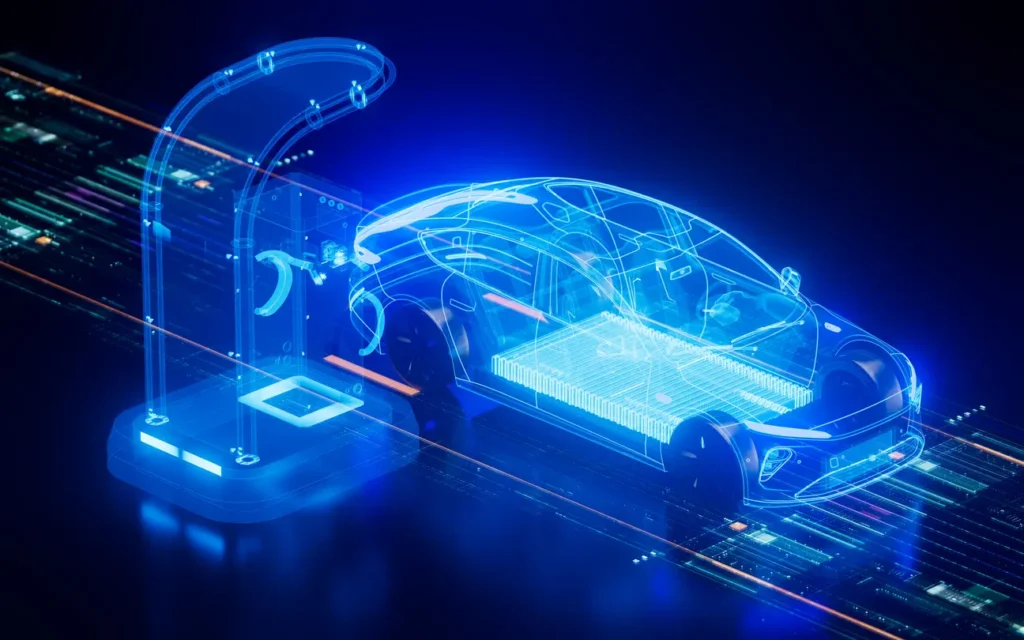

Electric vehicle (EV) battery packs, especially high-capacity lithium-ion systems, can release volatile organic compounds (VOCs) and electrolytic fumes during charging, thermal runaway, or heat soak. These emissions not only pose fire risks but also degrade air quality within battery enclosures. To mitigate this, battery manufacturers integrate advanced vapor management filters using acid-washed, thermally stable pelletized formulations from Vitronexa Carbon.

Engineered for high adsorption capacity and low outgassing, our carbon solutions effectively trap organic carbonates, electrolyte solvents, and other VOCs, preventing flammable gas buildup and maintaining the structural integrity of the battery system. Widely adopted by EV manufacturers and battery OEMs, this application supports safer, longer-lasting, and regulation-compliant energy storage systems.

© 2014 Copyrights Reserved by Vitronexa