At Vitronexa Carbon, infrastructure is not just a support system it’s the operational core of our promise reliability, repeatability, and regulatory confidence. Every element of our facility has been purpose-designed to meet the evolving demands of water purification, air filtration, and specialty-grade activated carbon applications. From sourcing to shipping, we operate in a closed-loop ecosystem where traceability, speed, and compliance converge seamlessly.

Our production facility is located in one of the world’s richest coconut-producing belts, giving us privileged access to high-quality, low-volatile coconut shells, the backbone of superior activated carbon. This location was chosen not for convenience, but for strategic operational advantage:

Your product’s journey starts with the finest raw material, sourced from the heart of South India.

Designed to scale. Engineered for precision.

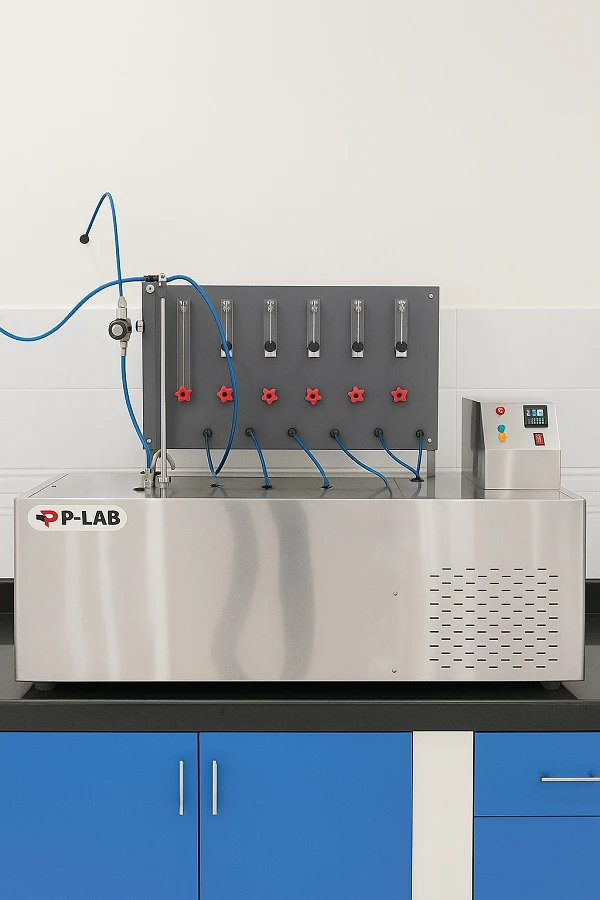

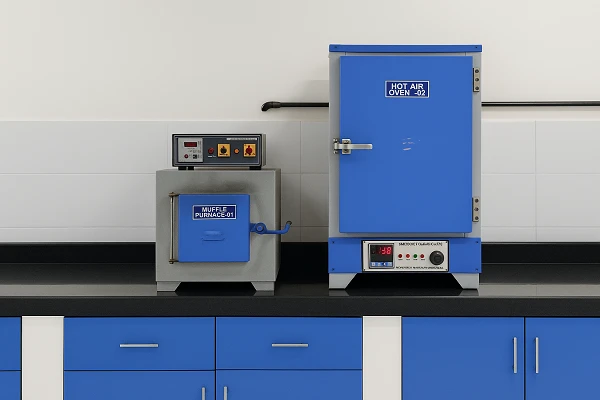

Our fully integrated manufacturing facility is built to handle an annual production capacity of 6,400 metric tonnes, with flexibility to adapt to diverse mesh sizes and industry specifications. The plant brings together steam-activated rotary kilns, dedicated acid-washing chambers, and precision mesh separation systems into a unified, synchronized operation.

We produce:

This high-capacity infrastructure enables us to serve bulk orders, customized formulations, and urgent international shipments all with the same level of consistency and quality assurance.

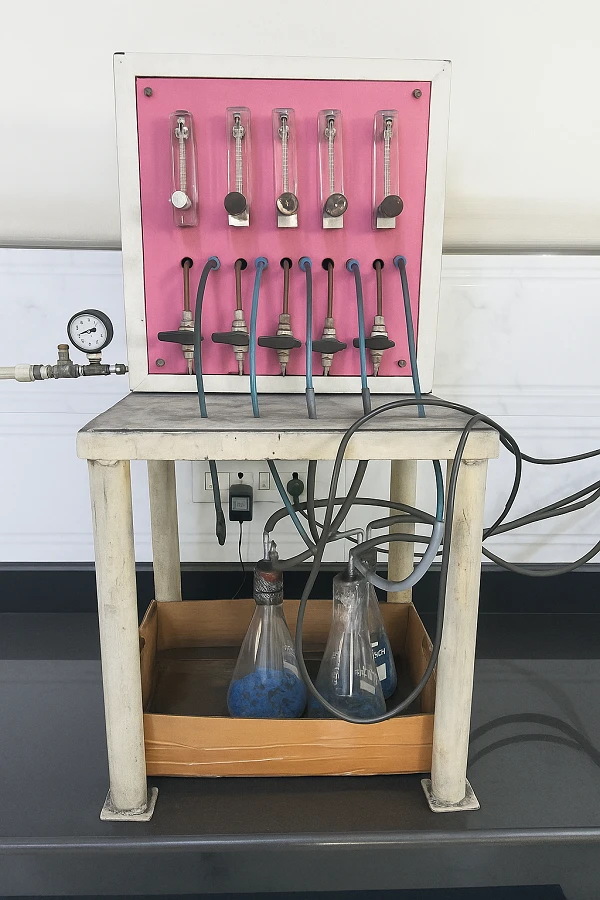

Our in-facility labs are equipped with ASTM & JIS compliant testing instruments to ensure every batch meets global benchmarks. With multi-point QC checkpoints, we validate:

Each batch is documented, traceable, and archived providing clients full transparency and accountability.

Strategically positioned near Thoothukudi Port, one of India’s most efficient and export-focused maritime gateways, our facility is built for seamless global logistics. This port access enhances our ability to meet international timelines and maintain cost-effective, compliant export operations.

Key Logistics Advantages:

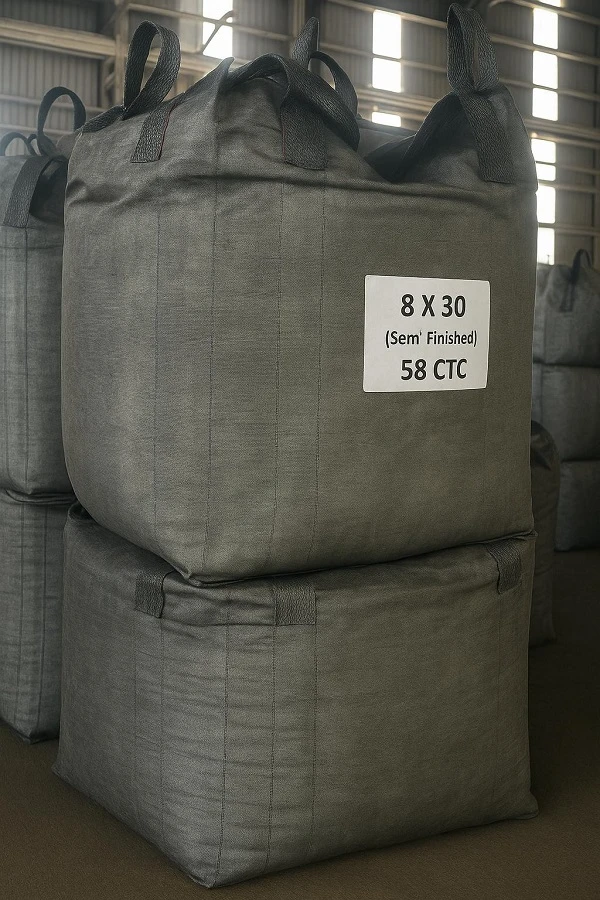

At Vitronexa Carbon, we maintain a meticulous warehousing and batch segregation system to ensure quality, consistency, and safety at every stage. Each product batch is carefully categorized based on its end-use application such as water purification, air and gas filtration, and other industrial or specialty-grade uses. We package our activated carbon in export-standard formats widely preferred by international buyers, including 25 kg and 50 kg HDPE-lined kraft paper bags for easy handling, as well as 500 kg and 550 kg jumbo bags for bulk shipments.

Our facility is designed for seamless storage operations with full traceability from production to dispatch. Strict zoning protocols are enforced to avoid cross-contamination between different product grades. Additionally, we incorporate climate-controlled storage areas for moisture-sensitive consignments, further ensuring that product quality remains uncompromised. This robust system supports smooth global logistics and enhances buyer confidence in every shipment we dispatch.

© 2014 Copyrights Reserved by Vitronexa